Improve the quality of the parts by using the flexibility of servo motor electric screw press

Author: haloong Time: 2019-05-27 16:05:29

Servo motor electric screw press is the use of permanent magnet servo motor has many functions such as power, speed change, and the execution, and speed has the characteristics of good controllability, direct drive press mechanism, adopt the adaptive torque control technology and computer control technology, using the digital technology (and the feedback control technology) control servo motor, can accurately control the position and speed of the slider, using a stamping mechanism to set the most suitable for a variety of stamping process and the slide block motion model, through the different program, implement process all kinds of the slider movement curve, get different workpiece deformation velocity, ensure the quality of workpiece.

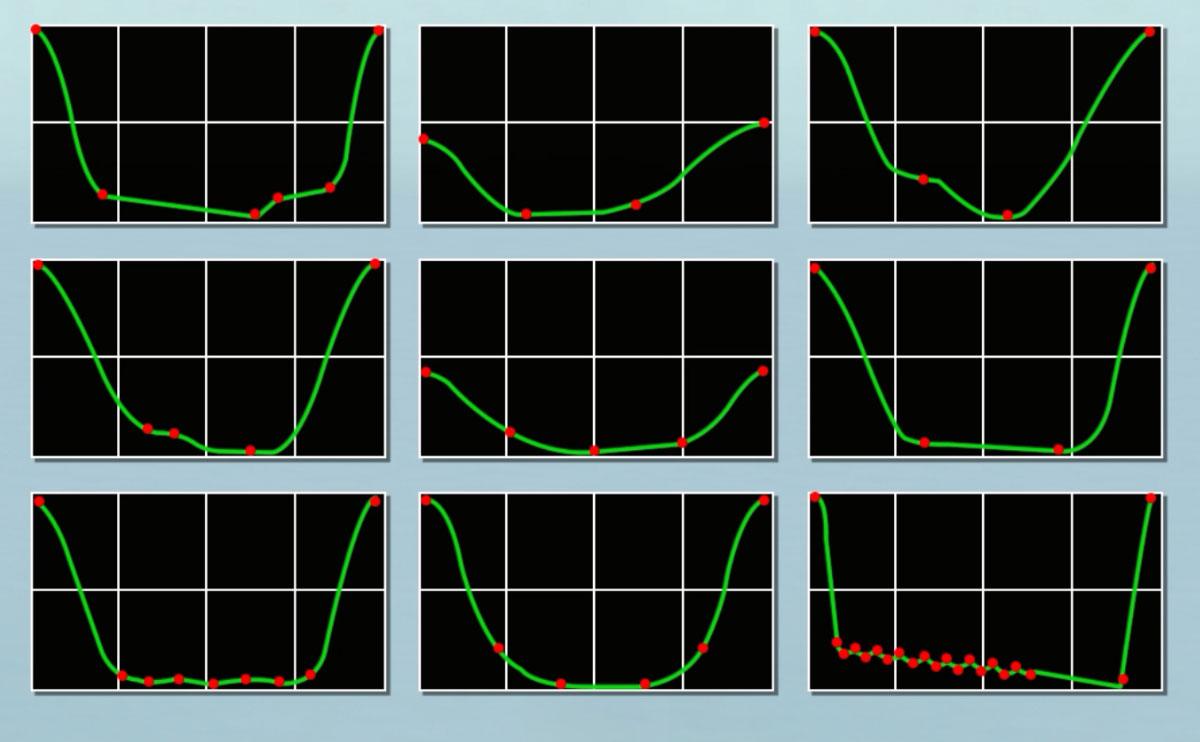

Press molding process curve

1.High precision of products :Through closed loop feedback control, always ensure the accuracy of the bottom dead centre. Restrain the burr of products , prevent the production of defective products.

2.The controllability of slider movement: Users can use this characteristic to compile the slider movement suitable for processing technology, effectively improve the precision and stability of the product, improve the die life and productivity, and can realize the mute blanking, can even expanding the scope of the processing (such as magnesium alloy stamping processing, etc.), suitable for blanking, deep drawing, stamping and bending process, and different characteristic curve.If the sliding block can be stopped to maintain pressure, the purpose is to improve the forming quality of the parts.

Servo CNC electric screw press can realize different molding process curve

3.From the perspective of stamping process, the main advantages of servo motor electric screw press are: improving the material utilization rate of the whole vehicle, reducing the purchase cost of the whole vehicle, improving the molding quality and surface quality, and control the precision of parts;