Molding of refractory material preparation process (part 1)

Author: haloong Time: 2020-05-28 08:51:22

The process by which the mud material is processed into a blank body with a certain shape by means of a brick press is called forming, and the formed blank body has a dense and uniform structure and a certain strength.

First, Molding methods

The molding methods of refractory brick products are as follows:

(1)Slip casting

The mud is injected into the plaster mould, which absorbs the water in the mud and forms a mud film with less water on the surface of the plaster mould. The longer the time is, the thicker the mud film will be. The placement time of plaster mold after grouting is determined mainly according to the required thickness of the product.

(2)Plastic molding

Plastic molding also known as extrusion molding, generally refers to the water content of 16~25% of the plastic state of the mud billet method, so that the plasticity of the strength of the mud through the mold hole molding method known as extrusion molding.

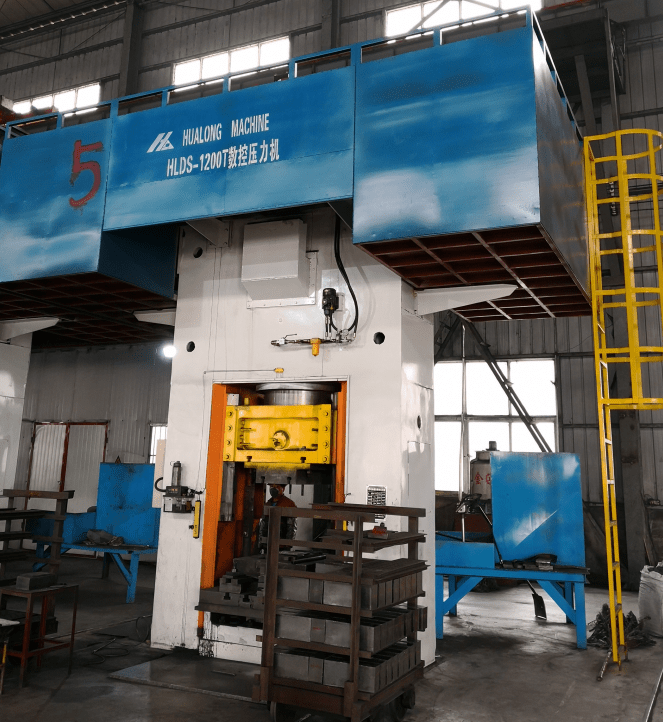

(3)Brick press molding

Press forming is also called semi-dry forming, which refers to the method of preparing the blank with the mud material with the water content of about 2~7. Generally use a variety of brick press, tamping machine, vibration mechanical molding.

(4) Casting and forming

This is a method of directly casting the material into products after melting it at high temperature. At present, it is mainly used for electrofused corundum, mullite and zirconium corundum.

Other molding methods of refractory materials include hot pressing molding and hot pressing injection molding. At present, refractory products are mainly formed by machine pressing. The following focuses on the introduction of machine molding.

Second,The brick press molding

In fact, the pressing process of common brick press is a process that compacts the particles and the air in the mud material to form a dense blank.The higher the density of the natural accumulation of mud, the smaller the friction between the particles, the greater the compression of the mud by unit action, and the higher the volume density of the brick. Therefore, adding some organic activators into the mud can improve the compacting degree of the brick.

After molding, the density of the brick along the direction of pressure is called layer density. Unidirectional pressure from the top of the brick, is generally dense on the thin, at the same level, then dense outside thin. In the production of refractory materials, in order to reduce or eliminate the layer density phenomenon caused by the pressing of the brick, the following methods are usually adopted:

(1) for thick products, generally use double-sided pressure.

(2) to improve the template machining accuracy and apply lubricating oil on the mold wall to reduce the friction between the mud and the mold wall.

(3) add some activators into the mud.

Isostatic molding is adopted, and multiple pressurization is adopted during the brick-pressing operation.