A refractory material enterprise using digital control, Cut energy use by 50%. How did he do it?

Author: haloong Time: 2021-09-26 11:35:14

In the market competition continues to intensify, double carbon environment increasingly rigid binding under the double pressure, in addition to clean production line, the elimination of backward technology and equipment, is actively asking for digital, digital management to benefit.

First, production automation, reduce the production cost of enterprises

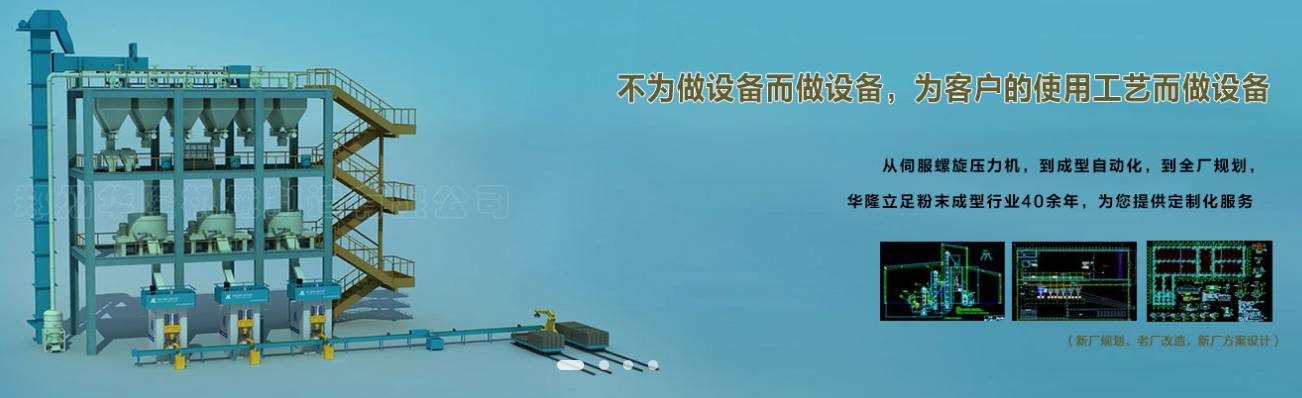

With the promotion and application of automation equipment, combined with the production process of firebrick, firebrick automatic production line, through the realization of automatic batching, automatic mixing, automatic weighing cloth, press automatic molding, automatic brick, automatic detection, brick taking, palletizing and other links of automation, It effectively improves the technological level of production equipment and product science and technology content of refractory material enterprises and reduces the production cost and management intensity of refractory material enterprises.

Second, intelligent production, enhance the production efficiency of enterprises

Based on information technology, a new generation of 5 g intelligent manufacturing management system for refractory industry, through the intelligent perception, human-computer interaction, data collection and analysis, the energy generated in the refractory industry production process visualization, visualization, equipment manufacturing visualization, remote services such as visual, targeted for refractories enterprises energy saving optimization solution. Accelerate the pace of building green factories in refractory material enterprises.

Through the Internet of things help refractories enterprises improve energy management system, to provide online integration operational service, wisdom of can use data acquisition, storage, and remote real-time monitor, at the same time for refractories enterprises can use the consumption and equipment operation condition on-line monitoring and data statistical analysis management, power companies, electricity, raw materials, and other comprehensive energy efficiency optimization management, improve efficiency, Reduce total energy bills.