What kinds of presses are commonly used in refractory brick factories?

Author: haloong Time: 2020-04-21 11:25:15

Molding process is the most important part of refractory production process.In the process of producing refractory brick,according to the density,refractory press sets moulding techniques,if the density is in the scope of specified requirement,the other index will be

no problem.There are three kind of presses most commonly seen in the refractory factory.

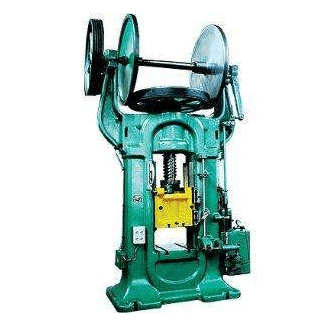

1,Friction press

friction press

Friction press also known as double disk friction press, when working, the vertical wheel and the flat wheel friction each other, lift the slider, store energy, and then release, impact pressure, to achieve the purpose of refractory pressing molding.The defect of friction energy transfer is that the energy transfer loss is large, the vulnerable parts are more, the labor intensity of the workers is large, the efficiency is low.From 1999, our country makel friction press into the elimination of products, With the cost control of different industry, enterprises began to eliminate friction press, especially the refractory industry, its elimination rate is particularly high nowadays.

2,Electric screw press

Electric screw press

Electric screw press is a new type of equipment, widely used, strong applicability, simple structure, large capacity.In order to facilitate the later mold design, the slide block designed by the electric screw press has no lower dead point, and the equipment is easy to debug and maintain.Electric screw press has small size, no vertical wheel, simple operation, safe operation, accurate and adjustable strike force, low mold wear rate, low maintenance cost, small workload.The electric screw press is well designed, with high precision of slide guide and strong anti-bias load, which is very suitable for one and more production lines. The electric screw press with belt drive has good shock resistance.

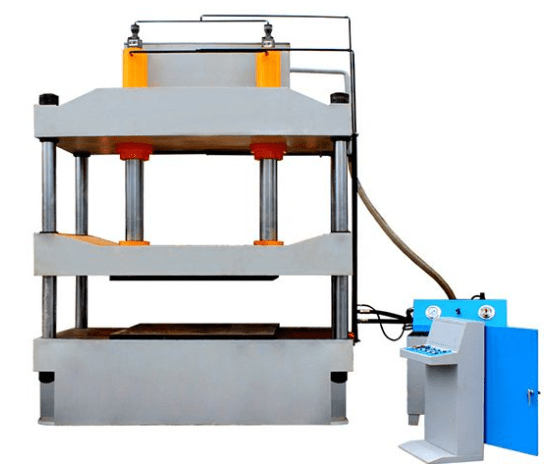

3, Hydraulic press

Hydraulic press

Hydraulic press is controlled by PLC machinery, electrical, hydraulic as one of the equipment. Hydraulic press is suitable for large-scale mass production, the equipment operating environment is good, but the production cost of hydraulic press is high, for enterprises, the equipment purchase cost is high, the early capital investment is large, and hydraulic press production flexibility is poor, brick replacement trouble, the technical requirements of maintenance workers on the high side. Cost - effective, as the electric screw press.

In summary, at present, the common types of press in refractory brick factory are: friction press, electric screw press, hydraulic press. Friction press belongs to the social elimination equipment, is gradually out of the market. Hydraulic press is suitable for large scale production, but the flexibility is poor, the cost is high. Electric screw press is simple in structure, easy to use, safe and easy to maintain.It is the main force of brick press equipment in modern refractory industry.