This automatic electric screw press is a multiple functional fire bricks molding machine.

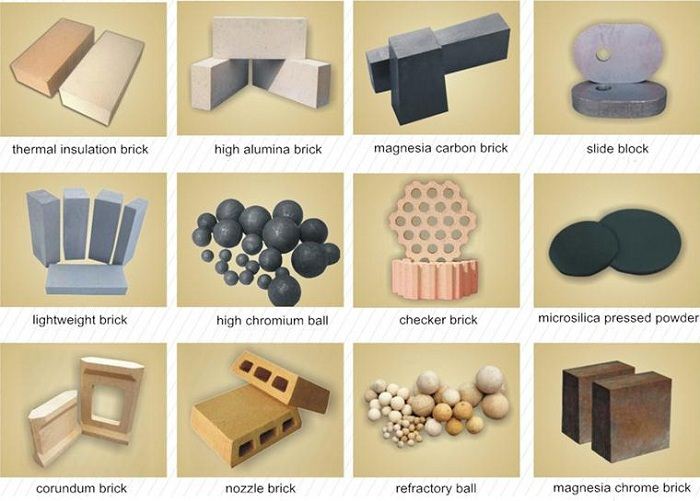

It is able to produce concrete bricks, high alumina bricks, high alumina corundum bricks, special shap bricks, magnesia bricks, SiC bricks, acid resistance bricks, acid proof bricks, special shapped bricks, carbon bricks, carbon graphite bricks, magnesite carbon bricks, alumina carbon bricks, silicon carbide bricks, diatomite bricks, moler bricks, zircon corundum bricks, alkali resistant bricks, cyanite bricks, magnesite calcium carbon bricks, magnesia alumina bricks, magnesite chromite bricks, monolithic refractory bricks, refractory nozzle, zircon mollite bricks, chemically bonded magnesite chrome bricks, magnesite spinel bricks, mullite bricks, multi purpose refractories, superduty bricks, high duty bricks and etc.

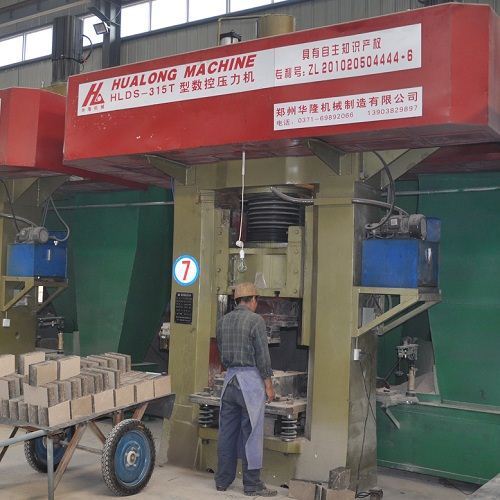

Application to forging industry:

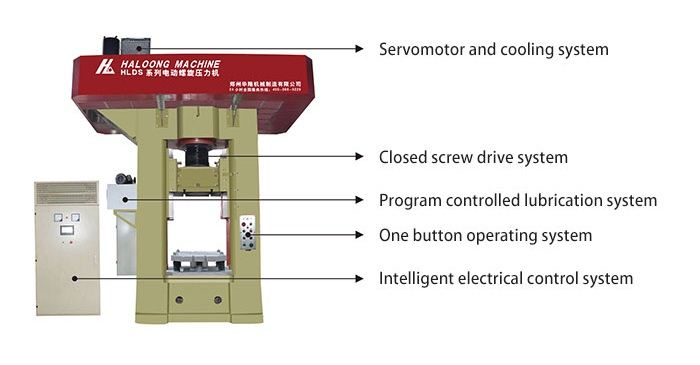

Product feature:

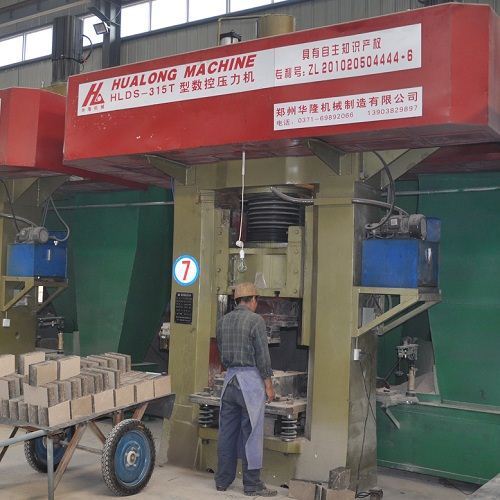

315T Electric Screw Press

315T Electric Screw Press

Good product consistency and high qualified rate. Easy to operate, strong overloading ability;

multiple safety protection, no bottom dead center;

Short transmission chain;simple structure, easy to maintain;

fully automatic molding then realize unmanned production;

free transmission between high & low speed and floating blow in single-stroke.

E-Mail:haloong@haloong.com

Description

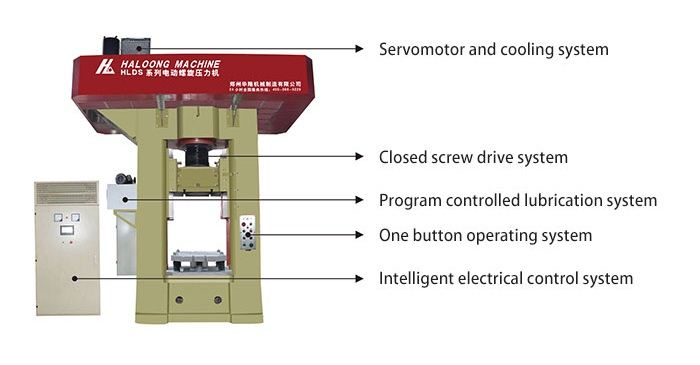

Product structure:

Product inroduce:

A electric screw press is a type of press machine in which the ram is driven up and down by a screw,which have the advantages of small volume,short of transmission chain,easy operation.

Cnc press is a new technology type of electric screw press ,which were driven by permanent magnet synchronous servo motor,and consist of mechanical pats such as framework, flywheel, screw nut, the slider, lubricating mechanism, braking mechanism and electric parts such as servo motor, electric control cabinet, operating button station.

Product inroduce:

A electric screw press is a type of press machine in which the ram is driven up and down by a screw,which have the advantages of small volume,short of transmission chain,easy operation.

Cnc press is a new technology type of electric screw press ,which were driven by permanent magnet synchronous servo motor,and consist of mechanical pats such as framework, flywheel, screw nut, the slider, lubricating mechanism, braking mechanism and electric parts such as servo motor, electric control cabinet, operating button station.

Product parameter:(B stands for static pressure)

| Model |

nominal pressure (KN/T) |

max. pressure (KN) |

slide stroke (mm) |

stroke No. (mm) |

die set height (mm) |

workatable size (mm) |

overall size (mm) |

motor (Kw) |

weight (T) |

|---|---|---|---|---|---|---|---|---|---|

| HLDS-30T | 300/30 | 600 | 300 | 40 | 670 | 550*550 | 1420*750*2136 | 4.2 | 1.2 |

| HLDS-60T | 600/60 | 1200 | 380 | 36 | 665 | 780*520 | 1550*800*2688 | 5.5 | 3.5 |

| HLDS-200B | 2000/200 | 4000 | 650 | 30 | 1000 | 900*660 | 2600*1600*4481 | 22 | 8.5 |

| HLDS-315B | 3150/315 | 6300 | 650 | 28 | 1100 | 1200*880 | 3150*2100*5328 | 37 | 21.5 |

| HLDS-400B | 4000/400 | 8000 | 700 | 28 | 1250 | 1200x1050 | 3300*2200*5675 | 52.3 | 28 |

| HLDS-630B | 6300/630 | 12000 | 750 | 26 | 1440 | 1250x1050 | 4000*2640*6432 | 84 | 53 |

| HLDS-800B | 8000/800 | 16000 | 750 | 26 | 1440 | 1300*1050 | 5000*2640*6545 | 52.3*2 | 57 |

| HLDS-1000T/B | 10000/1000 | 20000 | 700 | 22 | 1255 | 1350x1100 | 5600*2640*6620 | 78*2 | 75 |

| HLDS-1200B | 12000/1200 | 24000 | 700 | 22 | 1255 | 1450x1100 | 5600*2640*6620 | 84*2 | 78 |

| HLDS-1600B | 16000/1600 | 32000 | 800 | 20 | 1370 | 1800x1460 | 6200*3300*7305 | 136*2 | 118 |

| HLDS-2000B | 20000/2000 | 40000 | 800 | 18 | 1370 | 1900x1460 | 6500*3500*7600 | 160*2 | 162 |

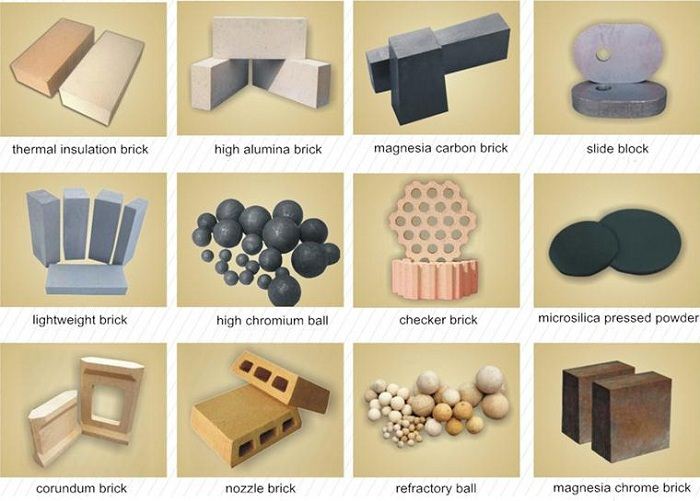

Application to refractory industry:

This automatic electric screw press is a multiple functional fire bricks molding machine.

It is able to produce concrete bricks, high alumina bricks, high alumina corundum bricks, special shap bricks, magnesia bricks, SiC bricks, acid resistance bricks, acid proof bricks, special shapped bricks, carbon bricks, carbon graphite bricks, magnesite carbon bricks, alumina carbon bricks, silicon carbide bricks, diatomite bricks, moler bricks, zircon corundum bricks, alkali resistant bricks, cyanite bricks, magnesite calcium carbon bricks, magnesia alumina bricks, magnesite chromite bricks, monolithic refractory bricks, refractory nozzle, zircon mollite bricks, chemically bonded magnesite chrome bricks, magnesite spinel bricks, mullite bricks, multi purpose refractories, superduty bricks, high duty bricks and etc.

Application to forging industry:

Product feature:

Servo motor drive system:

1. Small start-up current: little impact on power grid.

2. Motor starts when press is punching and stops when feeding material,picking out bricks,and cleaning mould. Energy-saving high to 55%.

3. High control precision: speed error is only 0.0001/r.

4. Stable running: no vibration and high torque when runs with low speed.

5. Quick response: very short time from static to rated speed, able to adjust speed freely between high speed to low speed within one stroke. Excellent effect of even hammer strike.

6. Speed overload function, achieves 2-3 times of rated speed.

Touch screen parameter setting system:

1. According to technology demands for different bricks, user can set the strike times, strike strength, and strike speed digitally. Able to achieve the effect of gently press for air-released, strike from gentle to heavy, the whole process of brick producing sequencing, reduce human factor to improve product quality.

2. Touch screen can real-time display the working status, monitor the producing process, detect and report the failure automatically.

3. Able to set password to protect production safety.

4. Touch screen has operation instruction and guideline.

Full automatic lubrication system:

1. Main engine adopts program controlled thin oil lubrication system, screw, nut and guide rail adopt program controlled grease lubrication system.

2. Oil shortage alarm function ensures equipment run healthily.

3. No need of maintenance, improves the service life of equipment and reduces the maintenance cost.

Multiple safety protection system:

1. Motor brake: through servo motor’s zero speed and torque to produce brake.

2. Mechanical brake: cylinder pushes friction plate to produce mechanical friction brake on the flywheel.

3. Emergency stop button: during working, it is able to press the emergency stop button at any time to make the slider back to TDC(top dead center) quickly.

4. Power loss protection: when power supply is abnormal, slider will stop immediately.

5. Optional equipment: can adopt demoulding outside the machine and add infrared raster.

One button operating system:

1. Only need to press the start button to finish the whole working process.

2. Fool-style operation, no need of professional press machine operator.

3. Laborsaving, only need 2 people to finish all the procedure of weighing, material feeding, moulding and brick discharging.

4. 3 types of striking technology: press button to match die, semi-auto strike and full-auto strike.

5. Emergency stop button can realize the emergency stop at any time.

1. Small start-up current: little impact on power grid.

2. Motor starts when press is punching and stops when feeding material,picking out bricks,and cleaning mould. Energy-saving high to 55%.

3. High control precision: speed error is only 0.0001/r.

4. Stable running: no vibration and high torque when runs with low speed.

5. Quick response: very short time from static to rated speed, able to adjust speed freely between high speed to low speed within one stroke. Excellent effect of even hammer strike.

6. Speed overload function, achieves 2-3 times of rated speed.

Touch screen parameter setting system:

1. According to technology demands for different bricks, user can set the strike times, strike strength, and strike speed digitally. Able to achieve the effect of gently press for air-released, strike from gentle to heavy, the whole process of brick producing sequencing, reduce human factor to improve product quality.

2. Touch screen can real-time display the working status, monitor the producing process, detect and report the failure automatically.

3. Able to set password to protect production safety.

4. Touch screen has operation instruction and guideline.

Full automatic lubrication system:

1. Main engine adopts program controlled thin oil lubrication system, screw, nut and guide rail adopt program controlled grease lubrication system.

2. Oil shortage alarm function ensures equipment run healthily.

3. No need of maintenance, improves the service life of equipment and reduces the maintenance cost.

Multiple safety protection system:

1. Motor brake: through servo motor’s zero speed and torque to produce brake.

2. Mechanical brake: cylinder pushes friction plate to produce mechanical friction brake on the flywheel.

3. Emergency stop button: during working, it is able to press the emergency stop button at any time to make the slider back to TDC(top dead center) quickly.

4. Power loss protection: when power supply is abnormal, slider will stop immediately.

5. Optional equipment: can adopt demoulding outside the machine and add infrared raster.

One button operating system:

1. Only need to press the start button to finish the whole working process.

2. Fool-style operation, no need of professional press machine operator.

3. Laborsaving, only need 2 people to finish all the procedure of weighing, material feeding, moulding and brick discharging.

4. 3 types of striking technology: press button to match die, semi-auto strike and full-auto strike.

5. Emergency stop button can realize the emergency stop at any time.

Online Message