Features of full automatic production line:

1. Unmanned production of refractory bricks.

2. Reduces the layber intensity of worker and reduces the pollution for environment.

3. Fast, efficient and accurate material feeding reduces the interference by people for material weighing and pouring.

4. Provides seamless docking solution for modern intelligent industrial plant, reduces the production cost.

Automatic material weighing and feeding system:

This automatic material weighing and feeding system is able to form the daily reports for various types of bricks' unit weight, daily output, monthly output, and annual output. Thus, it can provide the big data analysis with detail basic data for enterprise.

Technical data:

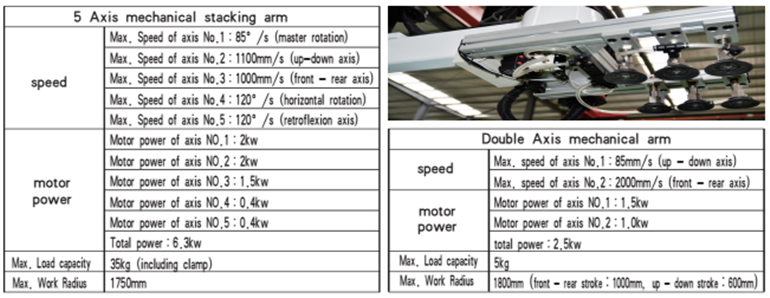

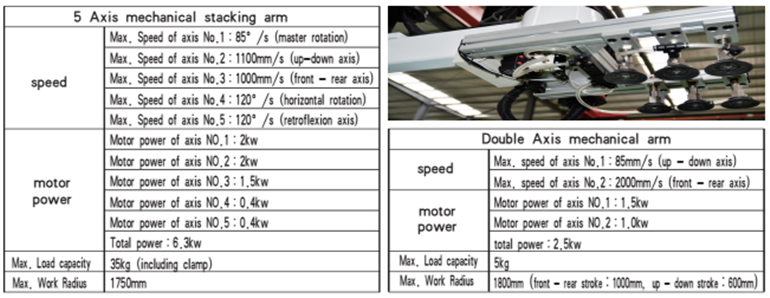

Robot for brick picking and stacking:

Technical data:

Full-auto Refractory Brick Line

Full-auto Refractory Brick Line

1.Automatically finish the whole process of electric material weighing,automatic material feeding,automatic brick forming and picking.Achieved the unmanned production of refractory bricks.

2.Featured with advantages of high precision weighting and feeding, reliable and flexible operation, convenient use and maintenance, high efficiency production, and high degree automation.

E-Mail:haloong@haloong.com

Description

Fully Automatic Refractory Brick Production Line

Summary:

Based on the accumulation of experience and technology for many years, according to the process of producing refractory bricks, Haloong develops and manufactures the fully automatic refractory brick production liine.

This production line can automatically finish the whole process of electric material weighing, automatic material distributing, automatic brick forming and picking. Achieved the unmanned production of refractory bricks.

Flow chart&features:

Based on the accumulation of experience and technology for many years, according to the process of producing refractory bricks, Haloong develops and manufactures the fully automatic refractory brick production liine.

This production line can automatically finish the whole process of electric material weighing, automatic material distributing, automatic brick forming and picking. Achieved the unmanned production of refractory bricks.

Flow chart&features:

Features of full automatic production line:

2. Reduces the layber intensity of worker and reduces the pollution for environment.

3. Fast, efficient and accurate material feeding reduces the interference by people for material weighing and pouring.

4. Provides seamless docking solution for modern intelligent industrial plant, reduces the production cost.

Automatic material weighing and feeding system:

This automatic material weighing and feeding system is able to form the daily reports for various types of bricks' unit weight, daily output, monthly output, and annual output. Thus, it can provide the big data analysis with detail basic data for enterprise.

Technical data:

Using range:3~15kg、15~30kg、30~60kg series

Feeding speed :1m/s ( It can be setting according to the process)

Weighing accuracy:≦30g

Robot for brick picking and stacking:

Technical data:

| Model |

nominal pressure (KN/T) |

max. pressure (KN) |

slide stroke (mm) |

stroke No. (mm) |

die set height (mm) |

workatable size (mm) |

overall size (mm) |

motor (Kw) |

weight (T) |

|---|---|---|---|---|---|---|---|---|---|

| HLDS-30T | 300/30 | 600 | 300 | 40 | 670 |

|

1420*750*2136 | 4.2 | 1.2 |

| HLDS-60T | 600/60 | 1200 | 380 | 36 | 665 | 780*520 | 1550*800*2688 | 5.5 | 3.5 |

| HLDS-200B | 2000/200 | 4000 | 650 | 30 | 1000 | 900*660 | 2600*1600*4481 | 22 | 8.5 |

| HLDS-315B | 3150/315 | 6300 | 650 | 28 | 1100 | 1200×880 | 3150*2100*5328 | 37 | 21.5 |

| HLDS-400B | 4000/400 | 8000 | 700 | 28 | 1250 | 1200x1050 | 3300*2200*5675 | 52.3 | 28 |

| HLDS-630B | 6300/630 | 12000 | 750 | 26 | 1440 | 1250x1050 | 4000*2640*6432 | 84 | 53 |

| HLDS-800B | 8000/800 | 16000 | 750 | 26 | 1440 | 1300*1050 | 5000*2640*6545 | 52.3*2 | 57 |

| HLDS-1000T/B | 10000/1000 | 20000 | 700 | 22 | 1255 | 1350x1100 | 5600*2640*6620 | 78*2 | 75 |

| HLDS-1200B | 12000/1200 | 24000 | 700 | 22 | 1255 | 1450x1100 | 5600*2640*6620 | 84*2 | 78 |

| HLDS-1600B | 16000/1600 | 32000 | 800 | 20 | 1370 | 1800x1460 | 6200*3300*7305 | 136*2 | 118 |

| HLDS-2000B | 20000/2000 | 40000 | 800 | 18 | 1370 | 1900x1460 | 6500*3500*7600 | 160*2 | 162 |

Online Message