Automatic metal forging presses

Metal forging press machine

Type: high-speed precision;

Nominal pressure:10000KN;

Max pressure:20000KN;

Slide stroke:760mm;

Stroke number:22 times/min;

worktable size:1300*1120mm ;

Punch Shape:closed punch;

Slider Movement:double action;

Slider Drive Mechanism: screw press

Controlling Mode:fully CNC grade;

Automatic Grade:fully automatic;

Power Source:electric;

Precision:high precision;

Certification:SGS,CE,ISO9001;

Condition: new

Transport Package:Main Body Bared,Accessories in Sea Wooden Case;

Motor for:78kw*2 ;

Motor:double motors ;

Weight: 73.8T ;

E-Mail:haloong@haloong.com

Description

Product Description:

Haloong press machine were equipment with servo motor,electric oil feeding system,damping design,touching screen,safty grating.Haloong electric screw press is designed for producing various types of metal wares. The press machine is also named as power screw press, forging / forge press, cold press, stamping press and punching machine. After replacing a proper mold,this electric screw press machine can also producing various refractory bricks. Therefore, the press machine can be named as hot die forging press or hot molding press.

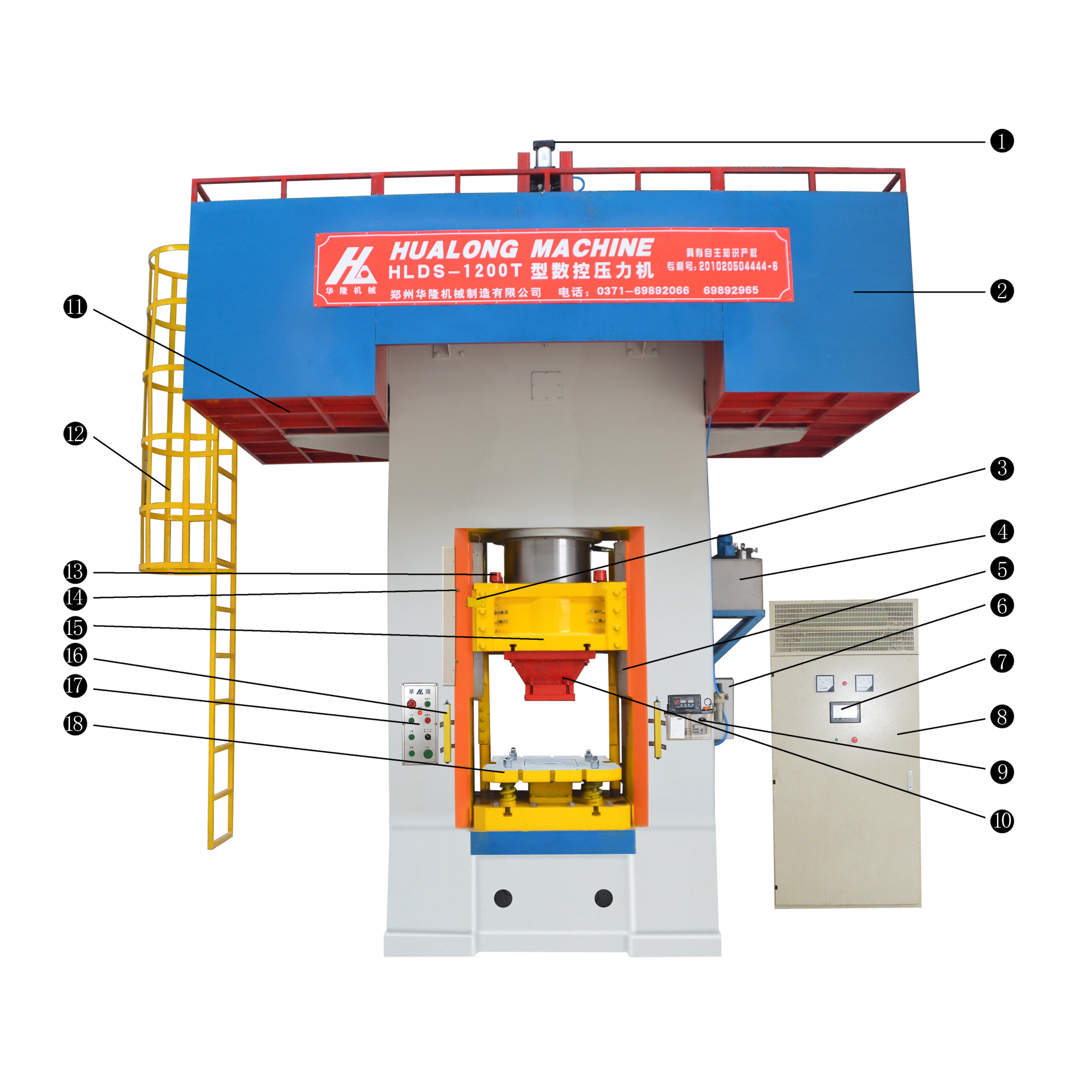

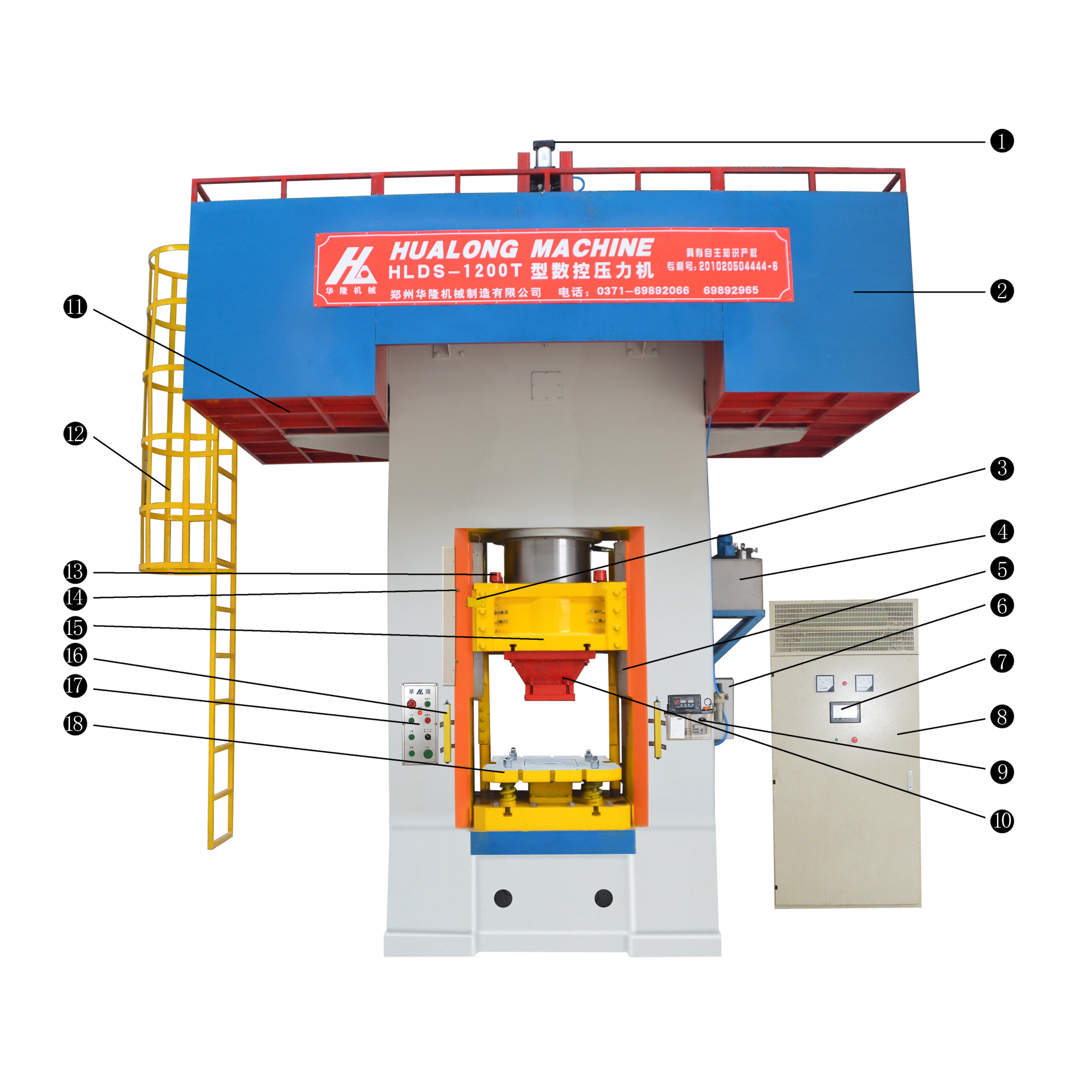

1. Brake device 2. Maintenance platform 3. Limit switch locating iron 4. Froced lubrication system

Features of HLDS series CNC servo press:

Haloong press machine were equipment with servo motor,electric oil feeding system,damping design,touching screen,safty grating.Haloong electric screw press is designed for producing various types of metal wares. The press machine is also named as power screw press, forging / forge press, cold press, stamping press and punching machine. After replacing a proper mold,this electric screw press machine can also producing various refractory bricks. Therefore, the press machine can be named as hot die forging press or hot molding press.

1. Brake device 2. Maintenance platform 3. Limit switch locating iron 4. Froced lubrication system

5. Guiderail 6. Brake and ejection system control cabinet 7. Servo control cabinet touch screen

8. Servo control cabinet 9. Digital electronic oil supply system 10. Secondary hammer

11. Water-cooled synchronous servo motor 12.Maintenance ladder 13. Bumper block

14. Limit switch 15. Slider 16.Satety raster 17. Intelligent button station 18. Floating pressure workbench

Features of HLDS series CNC servo press:

Servo motor drive system:

1. Small start-up current: little impact on power grid.

2. Motor starts when press is punching and stops when feeding material,picking out bricks,and cleaning mould. Energy-saving high to 55%.

3. High control precision: speed error is only 0.0001/r.

4. Stable running: no vibration and high torque when runs with low speed.

5. Quick response: very short time from static to rated speed, able to adjust speed freely between high speed to low speed within one stroke. Excellent effect of even hammer strike.

6. Speed overload function, achieves 2-3 times of rated speed.

Touch screen parameter setting system

1. According to technology demands for different bricks, user can set the strike times, strike strength, and strike speed digitally. Able to achieve the effect of gently press for air-released, strike from gentle to heavy, the whole process of brick producing sequencing, reduce human factor to improve product quality.

2. Touch screen can real-time display the working status, monitor the producing process, detect and report the failure automatically.

3. Able to set password to protect production safety.

4. Touch screen has operation instruction and guideline.

Full automatic lubrication system

1. Main engine adopts program controlled thin oil lubrication system, screw, nut and guide rail adopt program controlled grease lubrication system.

2. Oil shortage alarm function ensures equipment run healthily.

3. No need of maintenance, improves the service life of equipment and reduces the maintenance cost.

Multiple safety protection system

1. Motor brake: through servo motor’s zero speed and torque to produce brake.

2. Mechanical brake: cylinder pushes friction plate to produce mechanical friction brake on the flywheel.

3. Emergency stop button: during working, it is able to press the emergency stop button at any time to make the slider back to TDC(top dead center) quickly.

4. Power loss protection: when power supply is abnormal, slider will stop immediately.

5. Optional equipment: can adopt demoulding outside the machine and add infrared raster.

One button operating system

1. Only need to press the start button to finish the whole working process.

2. Fool-style operation, no need of professional press machine operator.

3. Laborsaving, only need 2 people to finish all the procedure of weighing, material feeding, moulding and brick discharging.

4. 3 types of striking technology: press button to match die, semi-auto strike and full-auto strike.

5. Emergency stop button can realize the emergency stop at any time.

1. Small start-up current: little impact on power grid.

2. Motor starts when press is punching and stops when feeding material,picking out bricks,and cleaning mould. Energy-saving high to 55%.

3. High control precision: speed error is only 0.0001/r.

4. Stable running: no vibration and high torque when runs with low speed.

5. Quick response: very short time from static to rated speed, able to adjust speed freely between high speed to low speed within one stroke. Excellent effect of even hammer strike.

6. Speed overload function, achieves 2-3 times of rated speed.

Touch screen parameter setting system

1. According to technology demands for different bricks, user can set the strike times, strike strength, and strike speed digitally. Able to achieve the effect of gently press for air-released, strike from gentle to heavy, the whole process of brick producing sequencing, reduce human factor to improve product quality.

2. Touch screen can real-time display the working status, monitor the producing process, detect and report the failure automatically.

3. Able to set password to protect production safety.

4. Touch screen has operation instruction and guideline.

Full automatic lubrication system

1. Main engine adopts program controlled thin oil lubrication system, screw, nut and guide rail adopt program controlled grease lubrication system.

2. Oil shortage alarm function ensures equipment run healthily.

3. No need of maintenance, improves the service life of equipment and reduces the maintenance cost.

Multiple safety protection system

1. Motor brake: through servo motor’s zero speed and torque to produce brake.

2. Mechanical brake: cylinder pushes friction plate to produce mechanical friction brake on the flywheel.

3. Emergency stop button: during working, it is able to press the emergency stop button at any time to make the slider back to TDC(top dead center) quickly.

4. Power loss protection: when power supply is abnormal, slider will stop immediately.

5. Optional equipment: can adopt demoulding outside the machine and add infrared raster.

One button operating system

1. Only need to press the start button to finish the whole working process.

2. Fool-style operation, no need of professional press machine operator.

3. Laborsaving, only need 2 people to finish all the procedure of weighing, material feeding, moulding and brick discharging.

4. 3 types of striking technology: press button to match die, semi-auto strike and full-auto strike.

5. Emergency stop button can realize the emergency stop at any time.

Main Parameters:

| Parameter Table of Electric Screw Firebrick Press Machine | |||

| 1600t | nominal pressure 16000KN | 400B | nominal pressure 4000KN |

| max pressure 32000KN | max pressure 8000KN | ||

| slide stroke 860mm | slide stroke 750mm | ||

| stroke number 20 times | stroke number 28 times | ||

| worktable size 1700*1460mm | worktable size 1200*1050mm | ||

| motor for 272kw | motor for 50kw | ||

| double motor | single motor | ||

| weight for 118T | weight for 26T | ||

| 1200t | nominal pressure 12000KN | 800T | nominal pressure 8000KN |

| max pressure 24000KN | max pressure 16000KN | ||

| slide stroke 760mm | slide stroke 760mm | ||

| stroke number 22 times | stroke number 24 times | ||

| worktable size 1320*1140mm | worktable size 1300*1050mm | ||

| 168kw | motor for 100kw | ||

| double motors | double motors | ||

| weight 80T | weight for 56.8T | ||

| 1000t | nominal pressure 10000KN | 630t | nominal pressure 6300KN |

| max pressure 20000KN | max pressure 12000KN | ||

| slide stroke 760mm | slide stroke 780mm | ||

| stroke number 22 times | stroke number 26 times | ||

| worktable size 1300*1120mm | worktable size 1250*1050mm | ||

| motor for 78kw*2 | motor for 78kw 84kw | ||

| double motors | double motors | ||

| weight for 73.8T | weight for 52T | ||

Online Message